|

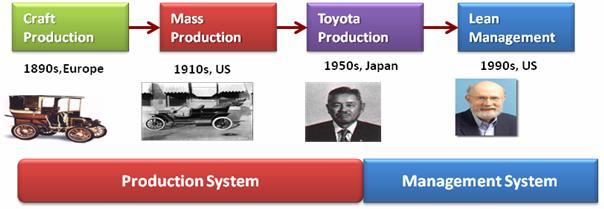

Initial Lean thinking were evident

in Arsenal in Venice in the 1450s, but Henry Ford was first to truly integrate an entire production process at Highland Park,

MI, in 1913 where he synthesised interchangeable parts with standard work and moving conveyors and created flow production.

Ford aligned manufacturing lines in process sequence using special-purpose machines and gauges to fabricate and assemble the

components going into the vehicle within a few minutes, and deliver perfectly fitting components directly on line. This was

a first revolutionary break from the shop practices of general-purpose machines grouped by process, which made parts that

found their way into finished products. The problem with Ford's system was not the flow but it was his inability to provide

variety. The Model T was not limited to black colour and also limited to one specification. All Model T chassis were essentially

identical up through the end of production in 1926. Practically every machine in the Ford Motor Company worked on a single

part number, and there were essentially no changeovers.

"Customers didn't have choice".

But the customers wanted variety and Ford lost his way. Other automakers responded to the need for many

models, each with many options, but with production systems with much longer throughput times. Over time they populated their

fabrication shops with larger and larger machines that ran faster and faster, apparently lowering costs per process step,

but continually increasing throughput times. Even worse, the time lags between process steps and the complex part routings

required ever more sophisticated information management systems culminating in MRP Systems.

As Kiichiro Toyoda,

Taiichi Ohno, and others at Toyota looked at this situation after World War II, and made a series of simple innovations

might make it possible to provide continuity in process flow and a wide variety in product offerings. They revisited Ford's

original thinking, and invented the Toyota Production System. Toyota right-sized machines in line with actual volume needed,

introducing mistake proofing to ensure quality, lining the machines in process sequence, and devised quick change over to

process small volumes of many part numbers, and having each process step notify the previous step of its current needs for

materials through its innovative Kanban system. All these made it possible to obtain low cost, high variety, high quality,

and very rapid throughput times to respond to changing customer desires. Also, information management could be made much simpler

and more accurate. LEAN TODAY

Continued success of TOYOTA

over past two decades created an enormous demand for greater knowledge about lean thinking. There are literally hundreds of

books and papers, not to mention thousands of media articles exploring the subject, and numerous other resources available

to this growing audience.

The thought process of lean was thoroughly described in the book The Machine That Changed the World

(1990) by James P. Womack, Daniel Roos, and Daniel T. Jones. In a subsequent volume, Lean Thinking (1996), James P. Womack

and Daniel T. Jones distilled these lean principles even further.

As

lean thinking continues to spread to every country in the world, leaders are also adapting the tools and principles beyond

manufacturing, to logistics and distribution, services, retail, healthcare, construction, maintenance, and even government.

Indeed, lean consciousness and methods are only beginning to take root among senior managers and leaders in all sectors today.

Misconception on Lean!

Businesses in all industries and services, including healthcare and governments,

are using lean principles as the way they think and do.

Many organizations choose not to use the word lean, but to label what they do as

their own system, such as the Toyota Production System or the Danaher Business System. Why? To drive home the point that lean

is not a program or short term cost reduction program, but the way the company operates.

The word transformation or lean transformation is often used to characterize a company

moving from an old way of thinking to lean thinking. It requires a complete transformation on how a company conducts business.

This takes a long-term perspective and perseverance.

The term "lean" was coined to describe Toyota's

business during the late 1980s by a research team headed by Jim Womack, Ph.D., at MIT's International Motor Vehicle Program.

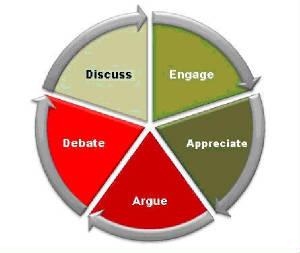

Engaging People "Lean thinking" is often misunderstood. It is not about cost cutting (the

old traditional focus of change) and it is certainly not about retrenching – i.e. less staff.

Rather

Lean Thinking is based on three values: Go See! (GEMBA) Ask Why? (Continuous Improvement) and Show Respect (to People who

create value) The system of "lean thinking" is the mutual reinforcing of these three values through

a structured process of principles and actions – that in its essence is fundamentally engaging of employees.

Appreciation is most engaging form of lean communication.

Lean thinking does not focus on fault-finding – concentrating on what is wrong. When people

are often criticised, they cease any meaningful communication with those who are criticising. This creates the antithesis

of learning.

In an environment of appreciation, people feel safe to make suggestions which form the

basis for a learning organisation, essential condition for lean transformation.

The Three Pillars of Lean

The three fundamental business issues that guides Lean transformation of any organisation:

Purpose: What customer problems will the enterprise solve to achieve its own purpose of prospering?

Process: How will the organization assess each major value stream to make sure each step is valuable, capable, available,

adequate, flexible, and that all the steps are linked by flow, pull, and levelling?

People:

How can the organization insure that every important process has someone responsible for continually evaluating that value

stream in terms of business purpose and lean process? How can everyone touching the value stream be actively engaged in operating

it correctly and continually improving it?

Thinking deeply about purpose, process, and people is key to "Lean Transformation".

What is Value?

The inherent worth of a product as judged by the customer and reflected in its selling price and market demand. For

any product or service, customer typically values for: Quality, Price, Delivery, and Service etc.

Who defines the Value? Value is always defined by customer.

Value in consumption and provision:

• Consumption is also a process: A series of actions consumers must perform

to obtain the value they seek.

• Provision is also a process: The actions that providers must perform between

the manufacturer and the customer to achieve the objectives of all three parties.

Today there is a gap between producers & customers that makes brilliant objects

less satisfying in practice than in theory. We need to enter the age of lean thinking, seamlessly integrating provision and

consumption.

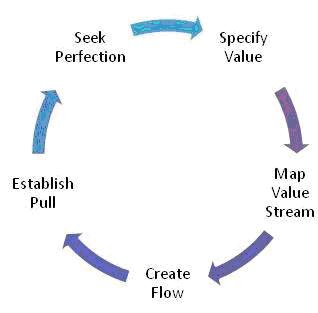

1. Specify value from the standpoint of the end customer by product family.

2. Identify all the steps in the value stream for each product family, eliminating whenever possible

those steps that do not create value.

3. Make the value-creating steps occur in tight sequence so the product will flow smoothly toward

the customer.

4. As flow is introduced, let customers pull value from the next upstream activity.

5. As value is specified, value streams are identified, wasted steps are removed, and flow and pull

are introduced, begin the process again and continue it until a state of perfection is reached in which perfect value is created

with no waste.

|